>200 million

cars have been coated with CathoGuard® 800

Coatings

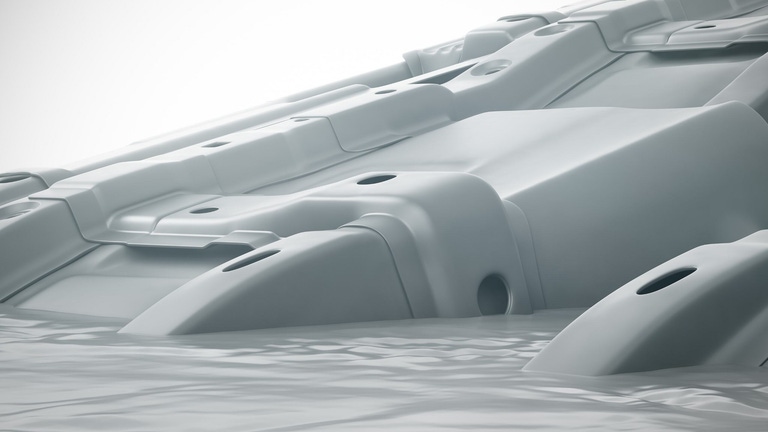

The e-coat protects the surface, edges and cavities of a car body from corrosion. In combination with the pre-treatment process, it provides an excellent base for applying subsequent paint layers.

The pre-treatment process prior to painting plays an essential role. It includes several steps to clean the car body, promote adhesion and provide a first barrier against corrosion. Afterward, the cathodic electrodeposition coat (e-coat) can be applied successfully. Only the intelligent combination of both – pre-treatment and e-coat – can ensure an excellent metal painted surface quality and optimal corrosion protection.

With CathoGuard® technologies, we provide a tailored product portfolio of automotive e-coat solutions. It covers products for car bodies as well as all metal parts including wheels, axles or chassis components.

>200 million

cars have been coated with CathoGuard® 800

Industry-Leading Expertise in E-Coat Performance & Service

By combining material and chemical efficiency with top-notch delivery and service execution, BASF supports automotive OEMs across their paint lines. Please click on the graphics to learn more.

Innovating for the Future of Automotive Coatings

A new age of automotive OEM has dawned — demanding a new road for success. Together with our partners in the automotive industry, we are dedicated to shape a sustainable future for mobility and actively reduce environmental impact.

< 1% solvent content reduces overall paint layer thickness

Tin-free and free of hazardous air particles (HAPs-free)

For all KPIs mentioned, actual potential depends on line condition, setup, specification, and the products which are compared.